About IVT

effective and efficient Motion Amplification services

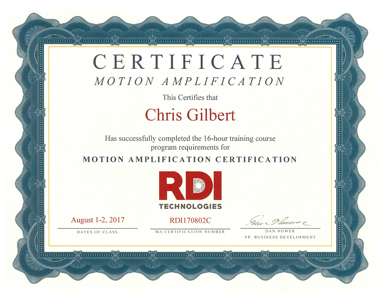

INNOVISION VIBRATION TECHNOLOGIES is a division of 6711588 CANADA INC. which has been providing mechanical consulting and services in the Oil and Gas industry for many years. Chris Gilbert (Owner/President) has specialized in, and is somewhat obsessed with rotating equipment and the technologies developed to ensure quality assembly, installation and healthy operation of the equipment and auxiliaries. When the IRIS M Motion Amplification technology was demonstrated to him, Chris immediately recognized how revolutionary and universal this system will be in troubleshooting and ensuring/improving equipment reliability.

INNOVISION is extremely passionate about this technology and providing customers across Canada with the most effective and efficient Motion Amplification services. Quality services with integrity is our focus. There are many reputable troubleshooting and reliability service companies. We aim to support them and ultimately meet the needs of their customers.

You will find INNOVISION’s integrity comes from a “we see it, we own it” attitude, and with this technology, we will see it! Our conscience will not allow us to simply identify your equipment issues and walk away if the customer requires assistance. We have developed a network of expert associates over the many years of consulting and can support all your equipment repair needs. Whether they are simply to participate in identifying the solution, overseeing the implementation and proving effectiveness after completion or providing an engineered solution and the complete implementation. INNOVISION can help with the solution.

INNOVISION is extremely passionate about this technology and providing customers across Canada with the most effective and efficient Motion Amplification services. Quality services with integrity is our focus. There are many reputable troubleshooting and reliability service companies. We aim to support them and ultimately meet the needs of their customers.

You will find INNOVISION’s integrity comes from a “we see it, we own it” attitude, and with this technology, we will see it! Our conscience will not allow us to simply identify your equipment issues and walk away if the customer requires assistance. We have developed a network of expert associates over the many years of consulting and can support all your equipment repair needs. Whether they are simply to participate in identifying the solution, overseeing the implementation and proving effectiveness after completion or providing an engineered solution and the complete implementation. INNOVISION can help with the solution.

About Chris Gilbert

The man behind the solutions

Chris has been a consultant in the oil and gas industry of Northern Alberta for 15 years. He has primarily been responsible for all Mechanical Commissioning and Start-up activities on several large SAGD projects for companies such as Suncor and ConocoPhillips. He has represented the client in the engineering house during design, witnessed equipment factory acceptance tests and tear-down inspections (including repairs when required), developed the pre-commissioning plans and monitored the activities, developed equipment witness criteria and monitored the activities, developed equipment testing procedures/acceptance criteria and participated in the activities and fully supported the equipment start-up through to steady state operation. He has been responsible for (and mentored many of) the support staff during the above activities.

Chris is proud that his services have been retained by the client after completion of every project due to his equipment knowledge, work ethics and demand for high quality. He has been retained in roles that allowed him to focus on his passion of rotating equipment – Maintenance Coordinator for Rotating Equipment, Rotating Equipment Specialist, Reliability Engineering RE Specialist, Maintenance Superintendent.

Prior to consulting in the oil and gas industry, Chris worked as a Millwright in the automotive manufacturing industry where he was thankful to gain valuable experience with hydraulics, pneumatics, robotics, CNC machinery, presses etc. and was obsessed with learning about all things that effect or control the equipment he is so passionate about. This is what planted the seed that grew into a desire for troubleshooting.

Chris is proud that his services have been retained by the client after completion of every project due to his equipment knowledge, work ethics and demand for high quality. He has been retained in roles that allowed him to focus on his passion of rotating equipment – Maintenance Coordinator for Rotating Equipment, Rotating Equipment Specialist, Reliability Engineering RE Specialist, Maintenance Superintendent.

Prior to consulting in the oil and gas industry, Chris worked as a Millwright in the automotive manufacturing industry where he was thankful to gain valuable experience with hydraulics, pneumatics, robotics, CNC machinery, presses etc. and was obsessed with learning about all things that effect or control the equipment he is so passionate about. This is what planted the seed that grew into a desire for troubleshooting.